Hydraulic pumps are the heartbeat of hydraulic systems, playing an essential role in converting mechanical energy into hydraulic energy. From heavy machinery to aerospace technology, hydraulic pumps are crucial in powering countless applications across industries. Whether you’re involved in construction, manufacturing, agriculture, or transportation, understanding the importance of hydraulic pumps and how to choose the right one for your system can make all the difference in performance, efficiency, and cost-effectiveness.

What is a Hydraulic Pump?

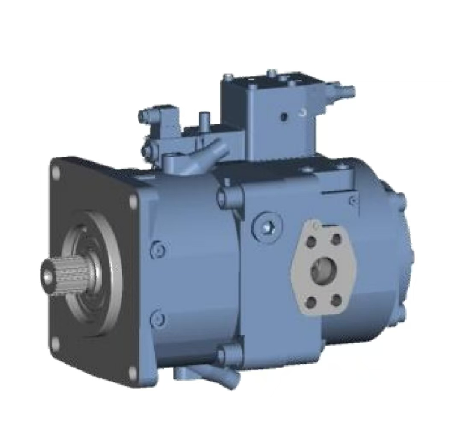

A hydraulic pump is a mechanical device that converts mechanical energy into hydraulic energy by moving hydraulic fluid through a system. It works by creating a flow of fluid under pressure, which is then directed to hydraulic cylinders, motors, or other components to perform work. Hydraulic pumps are designed to provide a consistent flow of fluid, which is essential for operating various machinery and equipment that rely on hydraulic power.

Types of Hydraulic Pumps

Hydraulic pumps come in various types, each suited for specific applications. Understanding these differences will help you choose the right pump for your system.

Gear Pumps

Gear pumps are the most common type of hydraulic pump, ideal for low to medium-pressure systems. They operate by using two interlocking gears to push fluid through the system. Gear pumps are simple, reliable, and easy to maintain, making them ideal for basic hydraulic systems.Piston Pumps

Piston pumps are more complex but offer higher efficiency and performance, especially in high-pressure systems. These pumps use pistons to move the fluid and are ideal for applications requiring precise control and variable flow. They are commonly found in large-scale industrial machines, construction equipment, and aircraft systems.Vane Pumps

Vane pumps use a set of vanes mounted on a rotor to move fluid through the system. These pumps provide smooth and consistent flow, making them suitable for medium to high-pressure applications. Vane pumps are often used in applications where noise and vibration levels need to be kept to a minimum, such as in automotive or industrial machinery.Diaphragm Pumps

Diaphragm pumps are used in systems where contamination of the hydraulic fluid must be avoided. These pumps operate by using a flexible diaphragm to move the fluid. They are often used in applications requiring low flow rates and in situations where the fluid needs to be isolated from the pump mechanism to prevent contamination.

Key Benefits of Hydraulic Pumps

High Power Density

One of the main advantages of hydraulic pumps is their ability to produce a large amount of power in a compact form. The power density of hydraulic systems is higher than most other mechanical power transmission systems, which makes hydraulic pumps ideal for high-force applications like construction machinery, forklifts, and excavators.Smooth and Precise Control

Hydraulic pumps allow for smooth, continuous, and precise control of machinery. The flow rate of the fluid can be adjusted easily, which helps control the speed and force of hydraulic systems. This makes them ideal for applications that require accurate and responsive control, such as in manufacturing or robotics.Ability to Handle High Loads

Hydraulic pumps are designed to handle high loads and pressures, making them indispensable in industries like construction, mining, and heavy lifting. Whether it’s lifting heavy equipment, powering presses, or operating cranes, hydraulic pumps can withstand extreme demands without compromising performance.Versatility

Hydraulic pumps can be used in a wide variety of applications, ranging from small-scale industrial machines to large construction equipment. This versatility is one of the reasons they are so widely used across many industries, including aerospace, automotive, agriculture, and energy.Reliability and Durability

Hydraulic pumps are built to last. When properly maintained, they can operate efficiently for long periods, even in harsh environments. Their durability makes them an ideal choice for applications that require reliable, long-term operation, like offshore drilling, mining, and power plants.

How to Choose the Right Hydraulic Pump

When selecting a hydraulic pump for your system, several factors need to be considered. Choosing the right pump will ensure that your system operates efficiently, reliably, and within your desired parameters.

Flow Rate

The flow rate is the amount of fluid the pump can move per unit of time, typically measured in liters per minute (LPM) or gallons per minute (GPM). It’s important to match the flow rate to your system’s needs to ensure proper operation. Too much or too little flow can affect the system’s performance.Pressure Requirements

Hydraulic pumps are designed to work under specific pressure ranges. Be sure to choose a pump that can handle the maximum pressure your system will need to operate at. This is particularly important for high-pressure systems like those found in heavy machinery or hydraulic presses.Pump Type

Depending on the application, you will need to choose between gear, piston, vane, or diaphragm pumps. For high-pressure and precision applications, piston pumps may be the best option, while gear pumps are suitable for low-to-medium pressure systems with simple designs.Efficiency

Hydraulic pumps vary in terms of efficiency, which is critical for minimizing energy consumption and reducing operational costs. Consider the efficiency of the pump in terms of the power it consumes and the hydraulic energy it produces.Operating Environment

Consider the operating conditions of your system. If the pump will be exposed to extreme temperatures, dust, or chemicals, you will need to select a pump that can withstand these conditions. Pumps with corrosion-resistant materials or coatings are essential for demanding environments.Maintenance and Longevity

It’s also essential to factor in the pump’s maintenance requirements. Some pumps, like gear pumps, are easier to maintain, while others, like piston pumps, may require more specialized care. Choose a pump that fits your maintenance capabilities and your desired longevity.

Common Applications of Hydraulic Pumps

Construction Equipment

Hydraulic pumps are critical for construction machinery, including excavators, bulldozers, and cranes. These pumps help power hydraulic systems for lifting, digging, and operating other heavy machinery.Agricultural Machinery

Tractors, combines, and other farming equipment use hydraulic pumps to power various systems, such as steering, lifting, and moving large equipment.Automotive Industry

In automotive applications, hydraulic pumps are used in systems such as power steering, brakes, and suspension. They ensure smooth and efficient operation, enhancing safety and performance.Aerospace

Hydraulic pumps in aerospace systems control a variety of functions, including landing gear operation, flight control surfaces, and actuation systems. These pumps must be reliable and operate in high-pressure environments.Manufacturing

Hydraulic pumps power machines in factories for pressing, molding, lifting, and cutting. They are essential in factories where high-pressure fluid is used to operate machinery with precision.

Conclusion

Hydraulic pumps are essential components in modern machinery and equipment. They enable power transmission in hydraulic systems, allowing machines to perform complex tasks with precision and reliability. Whether you are working in construction, automotive, aerospace, or agriculture, selecting the right hydraulic pump is crucial to ensuring optimal system performance, reducing downtime, and increasing the longevity of your equipment.

By understanding the different types of hydraulic pumps, their benefits, and how to select the right one for your application, you can enhance the efficiency, durability, and performance of your hydraulic system. Choose the right hydraulic pump to power your next big project and maximize your operational success.